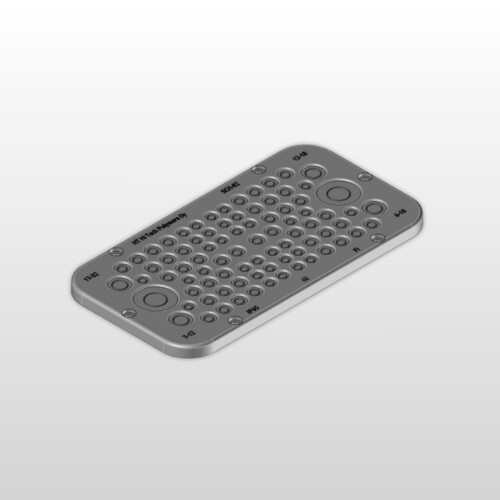

Cable entry plates and multi-flanges

for high cable density and secure sealing

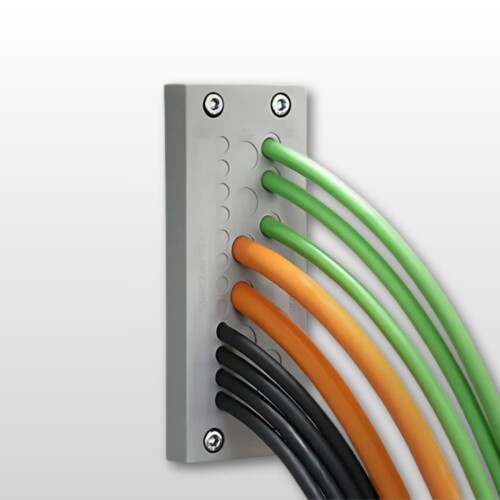

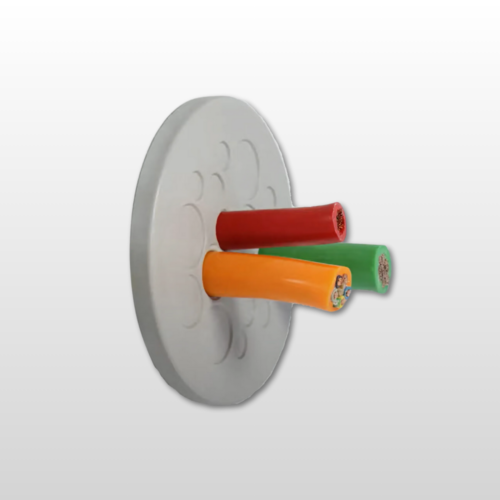

Cable entry plates and multi-flanges are used to introduce multiple cables through a common opening in control cabinets and enclosures.

The solution provides a simple and flexible cable entry where sealing and assembly can be adapted to the needs of the installation.

Explore our range of cable entry plates and multi-flanges

With high cable density / IP66 / UL Type 12

For extreme conditions, with strong strain relief | IP66 / IP68 | UL Type 12/4X

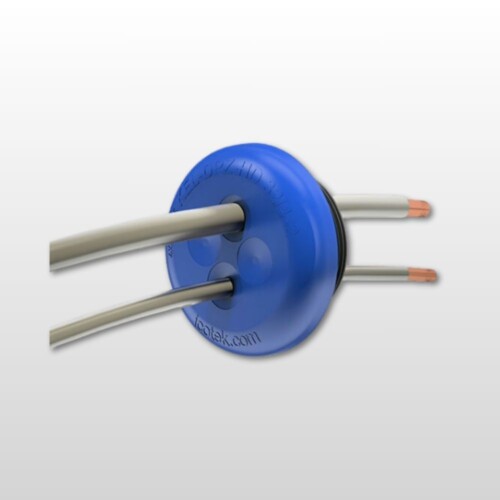

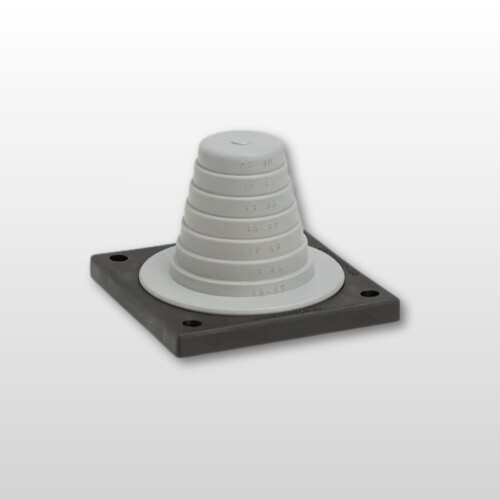

With pyramid-shaped membranes | For cables up to Ø 28 mm | Up to IP66

With high cable density | Up to IP65

In steel-reinforced rubber | IP65

ABS | IP54

For Rittal | IP65

For Schneider | IP65

""Snap-In" with thread M25 - M63 | IP65/IP66/IP68

With threading M25 - M63 | IP66/IP68 | UL Type 12/4X*

Hygienic | FDA compliant

With thread M32 - M63 | IP66/IP68

Robust, with strong strain relief | IP66/IP68 | UL Type 12/4X*

Hygienic | FDA compliant

Robust, with strong strain relief

IP66/IP68

With high cable density | Up to IP66 | UL Type 12

With high cable density | IP64 | UL Type 12

Fits metric holes M16 - M50 | IP65 | UL Type 12

With flexible sealing area | For cables up to Ø 36 mm | IP65

For cables up to Ø 70 mm, M25 - M85 | IP66/IP68 | UL Type 12/4X*

For cables up to Ø 68 mm | IP54 | UL Type 12

For cables up to Ø 115 mm | IP66 | UL Type 12

When should you choose cable entry plates or multi-flanges?

Cable entry plates and multi-flanges are the right choice when multiple cables are to be introduced through the same opening and where the installation requires simple adaptation.

They are often used in control cabinets where the wiring may change over time or where quick assembly is a priority.

Common uses:

- several unshielded cables

- installation environments with limited mounting space

- Retrofitting into existing enclosures

- applications where individual strain relief is not critical

When is this solution not the right choice?

Cable entry plates and multi-flanges are not always suitable in installations with high mechanical requirements or where each cable needs individual strain relief.

Avoid this solution when:

- cables are subjected to pulling or movement

- EMC requirements require shield connection

- high protection class per cable is crucial

Options in these cases:

What is the difference between different cable entry plates and multi-flanges?

Materials & workmanship

- elastomer or plastic material

- affects sealing and service life

Seal around cable

- pre-cut or punched openings

- affects enclosure class

Mounting in enclosure

- mounting via flange or cutout

- requires the correct hole pattern in the enclosure wall

If you need greater flexibility or retrofitting:

Related product areas

FAQ – Frequently asked questions about Cable entry plates and multi-flanges

Can cable entry plates withstand IP-rated environments?

Yes, cable entry plates can be used in IP-rated environments.

The degree of protection achieved depends on the design of the plate, its material and how well the bushing is mounted to the enclosure. Correct mounting is crucial to maintaining a seal against dust and moisture.

Can cables be added later?

Yes, cables can often be added later.

Many cable entry plates and multi-flanges are designed to allow the addition of cables without having to replace the entire entry, which facilitates service and future modifications.

When is a cable gland a better choice?

Cable glands are a better choice when each cable requires individual strain relief, high mechanical strength or specific EMC properties.

It is also suitable when only single cables are to be inserted and maximum sealing per cable is crucial.

Accessories

In metric sizes from M16-M85.

For multi-pin connectors and icotek's cable entry system

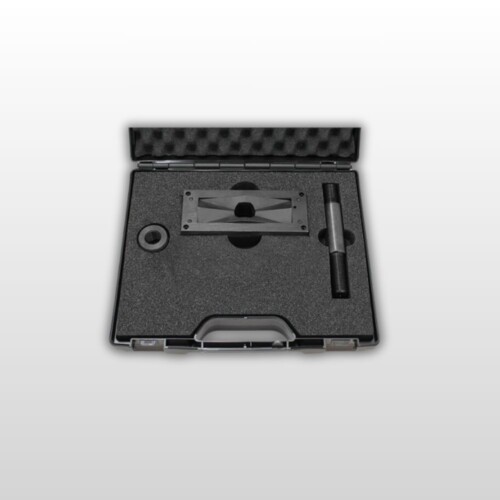

Hand hydraulic punch tool with accessories

Do you need help choosing the right cable entry plates and multi-flanges?

Unsure whether a cable gland plate, multi-flange or other solution is right for your installation?

Contact us and we will help you choose the right cable entry.