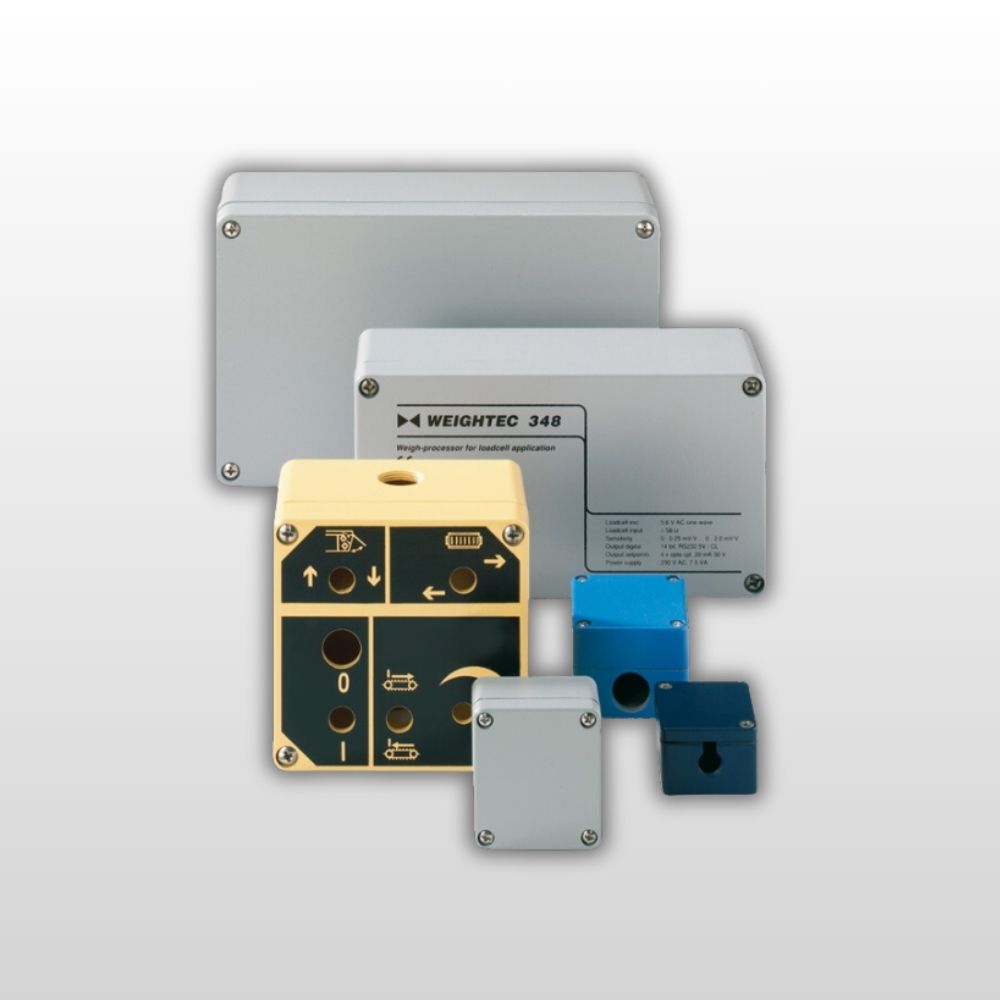

Cabinets & Boxes

electrical cabinets and control cabinets for industrial installations

Enclosures (electrical cabinets and control cabinets) are used to protect and organize electrical and automation equipment in industrial installations.

The choice of electrical cabinets and industrial cabinets is influenced by the environment, enclosure class, material requirements and how the equipment will be installed and serviced.

Explore our range of enclosures and enclosures

A wide standard range of equipment cabinet in painted sheet steel (RAL 7035) with high IP class and good impact resistance. The enclosures are suitable for many different industrial applications.

Stainless steel equipment cabinet with very high corrosion resistance. Recommended for outdoor environments and process and food industries with high hygiene requirements.

A wide range of plastic boxes and junction boxes in materials such as polycarbonate, ABS and glass fiber reinforced polyester (GRP). The enclosures offer great flexibility and good opportunities for customization.

Enclosures in aluminum with a wide temperature range, high corrosion resistance and good EMC properties. A stable choice for industrial and technically demanding applications.

When are electrical cabinets used?

Enclosures are used to collect, protect and structure electrical and electronic components in industrial installations. They function as electrical cabinets or control cabinets and are used in everything from simple control systems to more advanced automation and process solutions.

An electrical cabinet provides protection against external influences such as dust, moisture and mechanical stress, while also creating order for wiring, assembly and future service.

When are other enclosure solutions more suitable?

Enclosures are not always the most appropriate solution, especially when the installation is very limited or when only a few components need to be encapsulated.

Other enclosure solutions may be more suitable when:

- only individual components should be protected

- the installation space is very limited

- the components are already individually nested

- the need mainly concerns cable entry or connection

In these cases, smaller enclosures or simpler solutions are often a better choice:

Explore different types of electrical cabinets

Sheet metal equipment cabinets

Sheet metal enclosures are used in industrial environments where high mechanical strength and stable construction are required. They are well suited for installations where equipment is built up in stages and where serviceability and flexibility are important factors.

Stainless steel appliance cabinet

Stainless steel enclosures are used in demanding environments with high demands on hygiene, corrosion resistance and cleaning. They are common in the food, pharmaceutical, process and outdoor industries.

Plastic Enclosures

Plastic enclosures are used in applications where light weight, chemical resistance or electrical insulation are a priority. They are well suited for smaller installations and environments with limited mechanical impact.

Enclosures in aluminum

Aluminum enclosures combine low weight with good mechanical stability and efficient heat dissipation. They are often used in technical installations where thermal management and EMC properties are important aspects.

Important requirements and common pitfalls

The choice of cabinet or enclosure affects both the reliability and lifespan of the installation. An incorrect choice can lead to problems during operation, service or future expansion.

Common pitfalls:

- too low protection class in humid or dirty environments

- wrong choice of materials leading to corrosion or wear

- insufficient space for cabling and internal equipment

- underestimation of heat generation and need for cooling

If there is uncertainty about cable routing and penetrations, adjacent product areas should also be considered:

Customization and project support

- Hole drilling and machining

- Color customization

- Labeling and identification

- Contact Us

Guides and technical information

How to choose the right electrical cabinet

Compare cabinets and enclosures made of sheet metal, stainless steel, aluminum and plastic with a focus on IP class, environmental requirements and typical industries.

➡ How to choose the right enclosure: Material, IP class & accessories – Read the guide

IP65 vs IP66 – what's the difference?

Understand the difference in water protection according to EN 60529 and choose the right level for your installation.

Related product areas

FAQ – Frequently asked questions about cabinets and enclosures

What is the difference between enclosures and cabinets?

Enclosures are typically larger and designed for more complex installations with multiple components. Enclosures are more often used for smaller or more limited applications.

How do I choose the right IP class?

The correct IP class is selected based on the environment in which the enclosure is installed, such as dust, moisture or cleaning. Both enclosure and mounting affect the actual level of protection.

When are floor cabinets needed instead of wall cabinets?

Floor-standing cabinets are used when the installation requires a larger construction volume, higher load capacity or when wall mounting is not practically possible.

Do you need help choosing the right enclosure for your application?

Not sure which enclosure is right for your installation?

Contact us and we will help you choose the right solution based on environment, materials and future needs.