Plastic cable glands

for industrial installations

Plastic cable glands are used for secure cable entry into control cabinets and enclosures where low weight, chemical resistance and easy assembly are prioritized.

They are a common choice in industrial installations with moderate mechanical requirements and controlled environments.

Explore our range of plastic cable glands

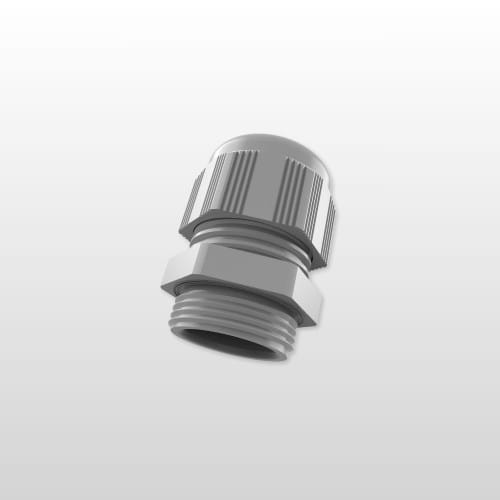

Industrial standard cable gland in polyamide

Snap-in cable gland in polyamide, without thread

High Performance cable gland in polyamide

High Performance cable gland in polyamide

For polyamide cable glands

For polyamide cable glands

When should you choose plastic cable glands?

Plastic cable glands are the right choice when the installation takes place in an indoor environment or protected industrial environment where corrosion, chemicals or high humidity are present.

Polyamide material provides good chemical resistance, low weight and sufficient mechanical strength for most control and automation cabinets.

Particularly suitable when:

- low weight is important

- many cable entries required

- assembly should be quick

- protection class up to IP68 is sufficient

When are plastic cable glands not the right choice?

Plastic cable glands are not the right choice in environments with high mechanical stress, risk of impact or where EMC requirements require electrical continuity between cable shield and enclosure.

Avoid plastic fittings when:

- the installation is outdoors without protection

- there is a risk of impact or vibration

- EMC requirements require shielded cable entry

- metal enclosure is used for grounding

In these cases, other solutions are usually more suitable:

What distinguishes different plastic fittings?

Material: Polyamide (PA)

- good chemical resistance

- temperature resistance for industrial environments

- UV resistance in some designs

Sealing & IP rating

- IP68 for dust and waterproof cable entry

- choice of seal affects service life

Strain relief & cable diameter

- The right span is crucial for sealing

- wrong dimension → risk of leakage and cable wear

In installations with many cables, pre-assembled connectors or limited space, a different solution may be more suitable than traditional plastic cable glands.

Related categories

FAQ - Frequently asked questions about plastic cable glands

Are plastic cable glands UV resistant?

Some plastic cable glands are UV-resistant, but not all.

UV resistance depends on material quality and additives in the polyamide. For installations in light-exposed environments or near windows, UV-resistant designs should be selected to avoid brittleness and reduced lifespan over time.

Can plastic fittings withstand oil and chemicals?

Yes, plastic cable glands made of polyamide generally have good resistance to many oils, greases and common industrial chemicals.

However, resistance varies depending on the type of chemical, temperature and exposure time. In the case of aggressive media or continuous exposure, the material selection should be verified before installation.

How do I choose the right size cable gland?

The correct size is chosen based on cable outer diameter, not conductor area.

The cable gland should cover the cable diameter within its specified range to ensure proper sealing and strain relief. A gland that is too large or too small can lead to reduced protection class and increased cable wear.

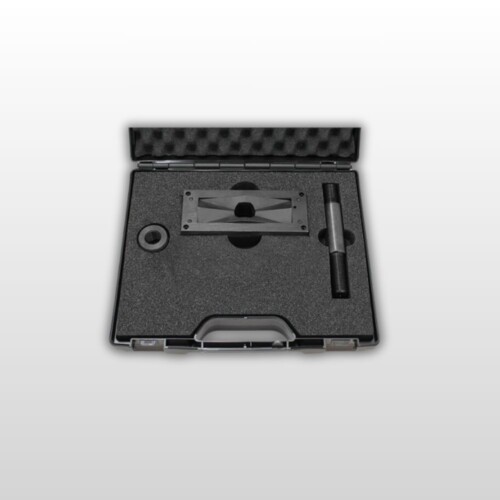

Accessories

For complete and safe installation, the correct accessories for cable glands are recommended.

In metric sizes from M16-M85.

For multi-pin connectors and icotek's cable entry system

Hand hydraulic punch tool with accessories

Do you need help choosing the right plastic cable gland?

Our experts will be happy to help you find the optimal solution for your installation.