Cable Glands EMC

shielded cable entry for industry

EMC cable glands are used to ensure electrical contact between cable shield and enclosure in installations with high EMC requirements.

Correct EMC screwing reduces electromagnetic interference and contributes to stable operation in sensitive industrial systems.

Explore our range of EMC cable glands

EMC 2 | Cable glands with fixed spring contact

EMC 3 | Cable glands with movable spring contact

EMC 4 | Cable glands with movable spring contact

For EMC cable glands in brass

When should you choose EMC cable glands?

EMC cable glands should be selected when shielded cables are used and the cable shield needs to be electrically connected to the enclosure.

They are crucial in installations where electromagnetic interference can affect function, safety or communication.

Common applications:

- frequency converter and motor control

- automation systems and control cabinets

- sensitive measuring and control equipment

- metal enclosures with grounding requirements

When are EMC cable glands not the right choice?

EMC cable glands are not necessary in installations where cables are unshielded or where EMC requirements do not apply.

Avoid EMC glands when:

- unshielded cables are used

- installation is simple and interference-free

- plastic enclosure used without grounding

Suitable options in these cases:

What distinguishes different EMC cable glands?

Display connection

- spring or clamp solution

- 360° contact to cable shield

- directly affects EMC performance

Materials & surface treatment

- brass or stainless steel

- surface treatment affects corrosion protection

Assembly & enclosure

- correct assembly determines function

- good contact with the enclosure wall is required

In case of complex wiring or many cables:

Related categories

FAQ - Frequently asked questions about EMC cable glands

When is 360° screen connection needed?

360° shield connection is needed when the cable shield is to be connected around the entire circumference of the cable to provide effective attenuation of electromagnetic interference.

This is particularly important in installations with high EMC requirements, such as frequency converters, motor control or fast communication, where point-to-point connection does not provide sufficient shielding.

Is metal screw connection sufficient without EMC function?

No, a standard metal gland without EMC function is not sufficient when the cable shield must be electrically connected to the enclosure.

Without a special EMC connector, there is no controlled shield connection, which can lead to poor EMC performance even if the screw connection is made of metal.

Does incorrect mounting affect EMC performance?

Yes, incorrect mounting can significantly affect EMC performance.

Poor contact with the cable shield or enclosure, incorrect tightening torque or dirty contact surfaces can impair the shield connection and thus reduce electromagnetic attenuation.

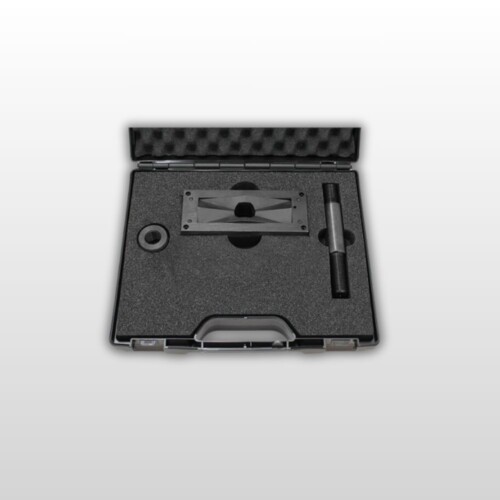

Tools for making holes in cabinets & enclosures

In metric sizes from M16-M85.

For multi-pin connectors and icotek's cable entry system

Hand hydraulic punch tool with accessories

Do you need help choosing the right EMC cable gland?

Unsure about EMC requirements or the right solution for your installation?

Contact us – we will help you choose the right cable entry.