Enclosures in aluminum

for industrial installations

Aluminum enclosures are used in industrial installations where low weight, good heat dissipation and mechanical stability are important factors.

Aluminum enclosures are particularly well suited for technical applications where both function and durability must be balanced.

Explore our range of aluminum enclosures

ALU | RAL7001 | IP66

Aluminium Enclosures

When should you choose aluminum enclosures?

Aluminum enclosures are a good choice when the installation requires a stable construction combined with low weight. The material is often used in industrial indoor environments where the enclosure needs to withstand mechanical impact without becoming unnecessarily heavy.

Aluminum is well suited when:

- heat from components needs to be dissipated effectively

- EMC properties are important in the installation

- the enclosure should be processed or adapted

- the installation takes place in an industrial indoor environment

When are other materials more suitable?

Aluminum is not always the most appropriate material in all environments. In some applications, other enclosure materials may provide better long-term performance or lower overall cost.

Other materials may be more suitable when:

- the enclosure is exposed to strong impacts, vandalism or heavy mechanical stress

- the environment is very humid or chemically aggressive

- high hygiene requirements or frequent cleaning are present

- low cost and easy handling are prioritized

In these cases, alternative solutions are often chosen:

What distinguishes different aluminum enclosures?

Materials and surface treatment

Aluminum enclosures are available with different surface treatments that affect corrosion protection and appearance. The choice of surface treatment is important for both longevity and environmental resistance.

IP rating and sealing

Enclosure class depends on design and sealing. Correct design is required to protect the equipment against dust and moisture in the relevant environment.

EMC properties

Aluminum has natural EMC advantages over plastic. For EMC-sensitive installations, the choice of material can contribute to better interference protection.

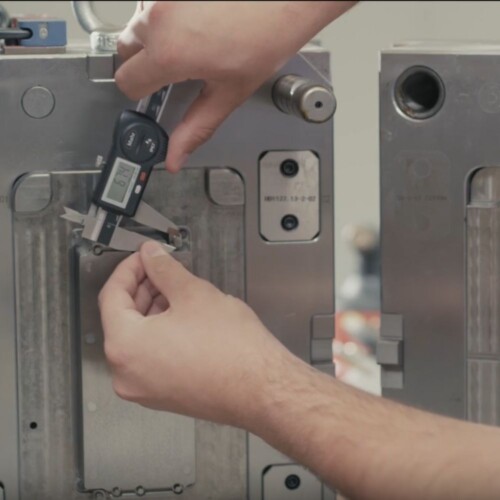

Assembly and processing

Aluminum is relatively easy to process, which facilitates the assembly of cable glands, actuators and other components.

Related product areas

FAQ - Frequently asked questions about aluminum enclosures

When is aluminum better than plastic?

Aluminum is often better when the installation requires higher mechanical stability, better heat dissipation, or improved EMC properties.

Do aluminum enclosures have EMC advantages?

Yes, aluminum contributes to basic electromagnetic shielding and is often used in EMC-sensitive applications.

Can aluminum enclosures withstand outdoor environments?

Aluminum enclosures can be used outdoors if they are properly surface-treated and have the correct enclosure rating, but in highly corrosive environments other materials may be more suitable.

Accessories - Customization

Customize your Box

Customize your Box

Customize your Box

Customize your Box

Do you need help choosing the right aluminum enclosure?

Not sure if aluminum is the right material for your application? Contact us and we will help you choose the right enclosure based on environment, requirements and application.