Grounding and EMC

for control cabinets and industry

Grounding and EMC are fundamental for reliable and interference-free industrial installations.

The right grounding solution and EMC management reduces the risk of operational disruptions, communication problems and unwanted electromagnetic emissions.

Explore our range of products for grounding and EMC

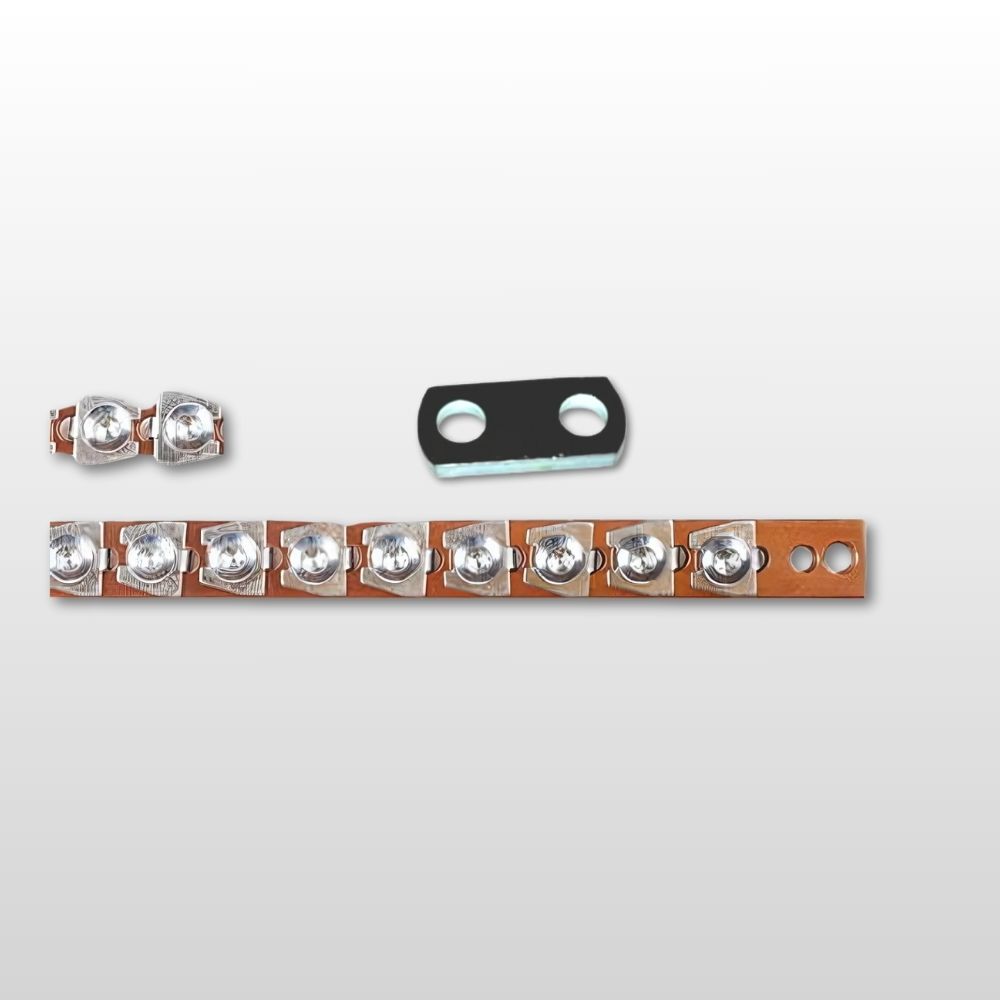

Potential equalization

Earthing bars in copper or brass with caps for cable dimensions up to 75 mm².

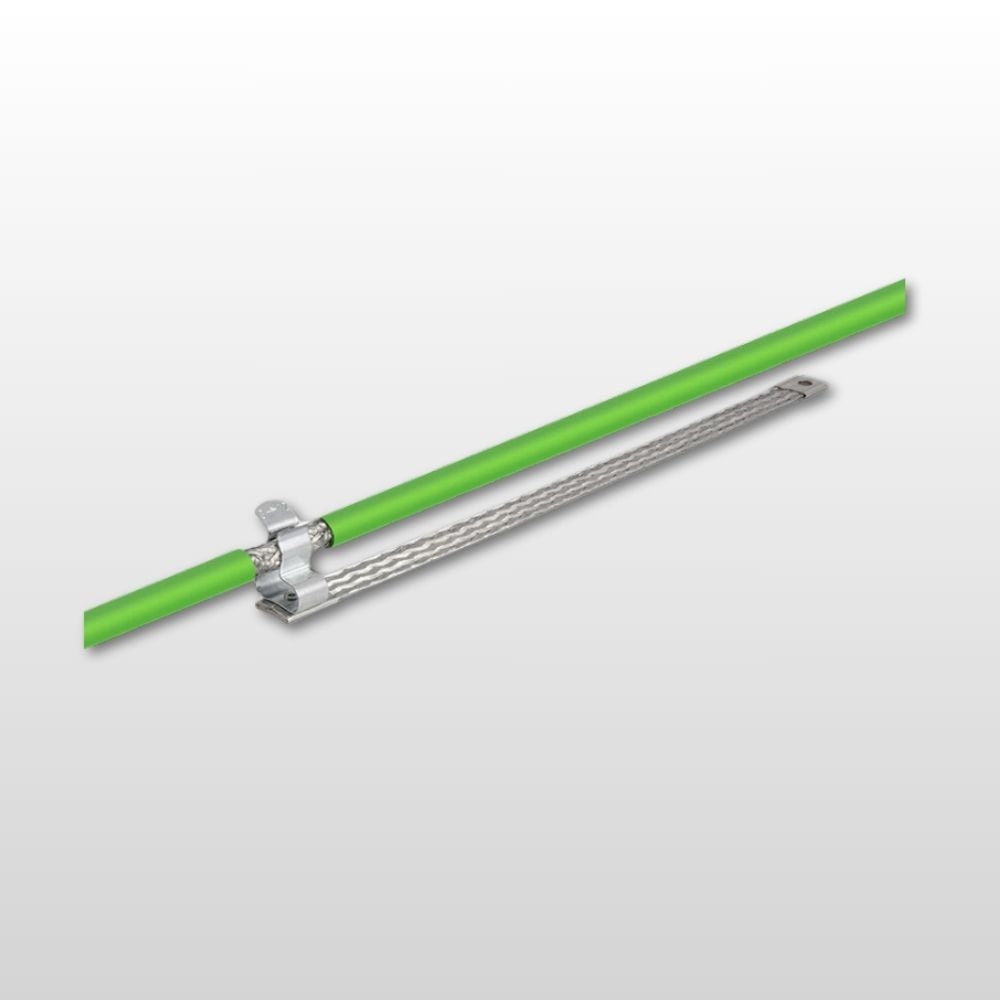

Potential equalization

Flexible E-Cu grounding braids in several lengths for different connection dimensions, UL approved.

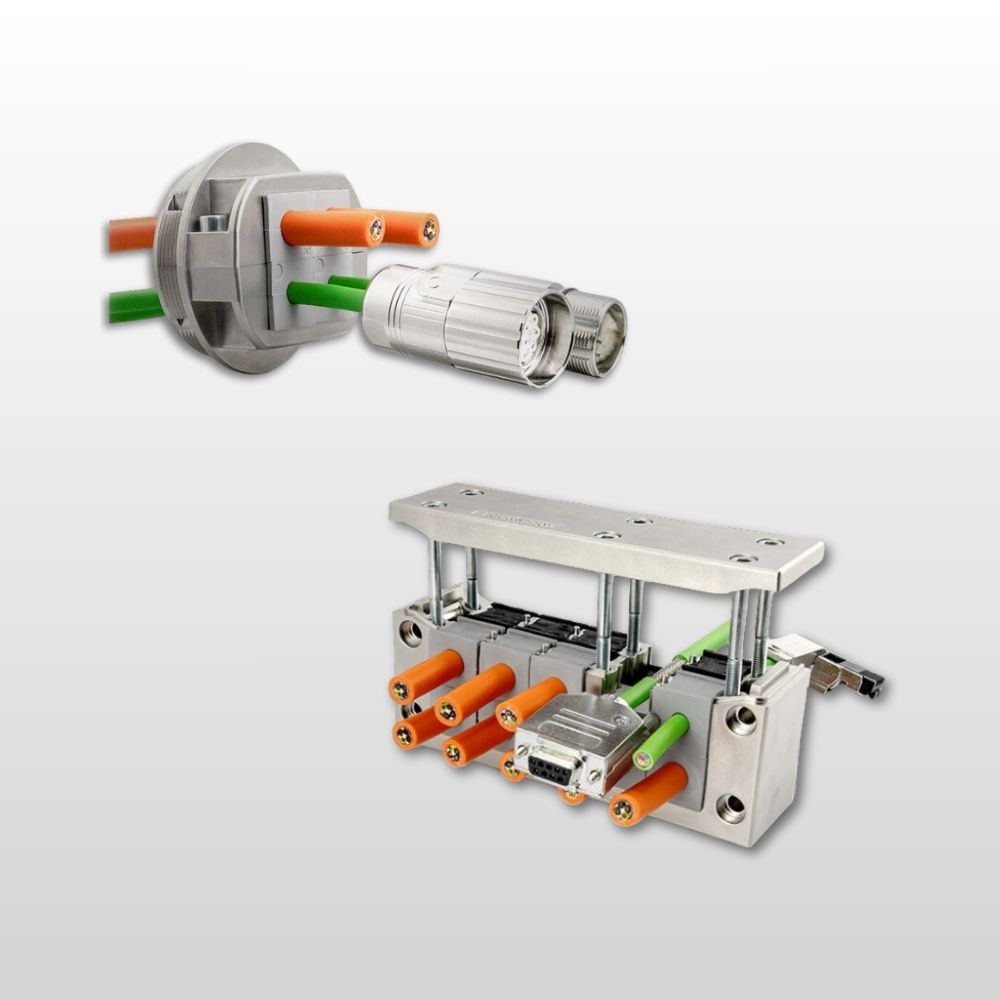

360° shielding & EMC grounding

Shield clamps from Icotek with an assembly-friendly and space-saving design in several versions.

Split EMC frames

EMC glands and divisible bushings for standard and connected cabling.

When are grounding and EMC solutions used?

Grounding and EMC solutions are used in industrial installations where electrical and electronic systems need to be protected against interference and potential differences. They are particularly important in automation systems, machines and control cabinets with frequency converters, control systems and communications.

A correct grounding and EMC structure contributes to stable operation, personal safety and compliance with applicable standards.

When are simpler solutions sufficient?

Not all installations require advanced EMC solutions. In simpler applications with low noise levels and limited electronics, basic grounding may be sufficient.

Simpler solutions may be sufficient when:

- the installation contains few sources of interference

- signal and power levels are low

- no sensitive communication systems are used

- surrounding environment is electromagnetically uncritical

However, in more complex systems, the requirements for structured grounding and EMC components increase.

Important requirements and common pitfalls

Incorrect or inadequate grounding is a common cause of EMC problems in industrial installations.

Common pitfalls:

- unclear or too long ground connections

- poor contact between cable shield and enclosure

- multiple ground points without a well-thought-out structure

- grounding that is not adapted to the frequency content of the installation

A well-thought-out grounding strategy should be developed early in the project.

Various solutions in grounding and EMC

Grounding bars

Grounding bars are used to collect protective earth and create clear grounding points in control cabinets and electrical installations.

Cable Clamps

Shield clamps are used to connect cable shields to ground and reduce electromagnetic interference in signal and power cables.

EMC cable entries

EMC cable glands are used when cable shields need to be effectively connected to the enclosure to achieve good EMC performance.

Earthing braids and earthing straps

Earthing braids are used for potential equalization between different parts of the installation where flexible connection is required.

Related product areas

Guides

Learn how shield clamps and EMC glands reduce interference in demanding industrial environments.

➡ How EMC shielding works and how do I protect my equipment – Read the guide

FAQ – Frequently asked questions about grounding and EMC solutions

Why is grounding important for EMC?

Proper grounding reduces the risk of electromagnetic interference by creating controlled return paths for interference currents

When are EMC components needed in addition to basic grounding?

In installations with sensitive electronics, high frequencies or a strong interference environment, supplementary EMC components are often required.

Does cabling affect EMC performance?

Yes, cabling, separation of signal and power, and correct shield connection have a major impact on EMC properties.

Do you need help with grounding and EMC?

Our experts will be happy to help you find the optimal solution for your installation.