Metal cable glands

for mechanically demanding and industrial environments

Metal cable glands are used in industrial installations where high mechanical strength, EMC properties and long service life are crucial.

They are an obvious choice in demanding environments, outdoor installations and applications with shielded cables.

Explore our range of metal cable glands

Industrial standard cable glands in brass

Industrial standard cable gland in brass with double sealing

Industrial standard cable glands in stainless steel

For cable glands in brass & stainless steel

When should you choose metal cable glands?

Metal cable glands are the right choice when the installation is exposed to mechanical stress, vibrations or where EMC requirements require electrical continuity between cable and enclosure.

Metal materials such as brass or stainless steel provide high strength, good sealing and the possibility of effective grounding.

Particularly suitable when:

- the installation is outdoors or in a harsh industrial environment

- shielded cables are used

- the casing is made of metal

- Long service life and operational reliability are prioritized

When are metal cable glands not the right choice?

Metal cable glands are not always necessary in simpler installations where environmental requirements are low and where EMC or mechanical strength are not crucial.

Avoid metal fittings when:

- the installation takes place in a protected indoor environment

- low weight is a priority

- many cable entries required at low cost

Options in these cases:

What distinguishes different metal fittings?

Material: brass or stainless steel

- brass: robust, cost-effective, common in industry

- stainless steel: high corrosion resistance, hygienic environments

EMC function

- metal provides electrical contact with the enclosure

- enables effective shielding and grounding

Sealing & IP rating

- IP68 common in demanding environments

- The quality of the seal determines the service life

When special EMC requirements exist:

Related product areas

FAQ - Frequently asked questions about metal cable glands

Are metal fittings always better than plastic?

No. Metal cable glands are better when the installation requires high mechanical strength, EMC function or long life in demanding environments.

In simpler indoor installations without EMC requirements, plastic glands can be a fully adequate and more cost-effective alternative.

When is EMC functionality required in the cable gland?

EMC function is required when shielded cables are used and the cable shield must be electrically connected to the enclosure.

It is common in installations with frequency converters, motor controls or sensitive electronics where electromagnetic interference must be limited.

Can metal screw connections withstand outdoor environments?

Yes, metal fittings are well suited for outdoor environments.

Brass or stainless steel versions with the right seal and surface treatment provide good resistance to moisture, temperature variations and mechanical impact. The choice of material should be adapted to the corrosion level of the environment.

Accessories

In metric sizes from M16-M85.

For multi-pin connectors and icotek's cable entry system

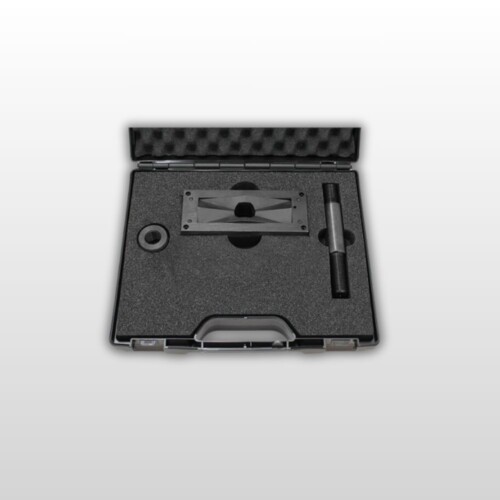

Hand hydraulic punch tool with accessories

Do you need help choosing the right metal cable gland?

Are you unsure about material selection or EMC requirements?

Contact us and we will help you choose the right solution.