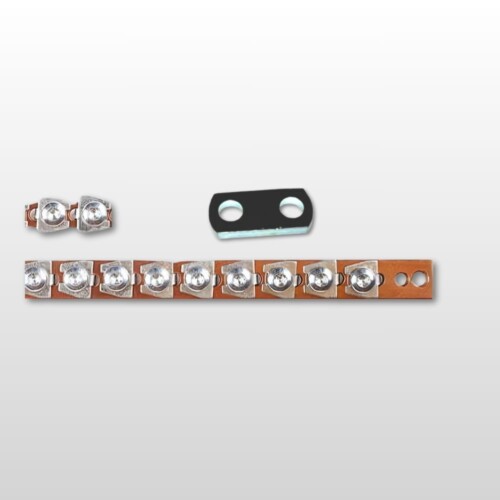

Bus Bars

for safe grounding in control cabinets

Bus bars are used to collect and distribute protective earth in control cabinets and electrical installations.

The right Bus bar ensures correct potential equalization, service-friendly installation and stable operation in industrial environments.

Explore our range of Bus bars

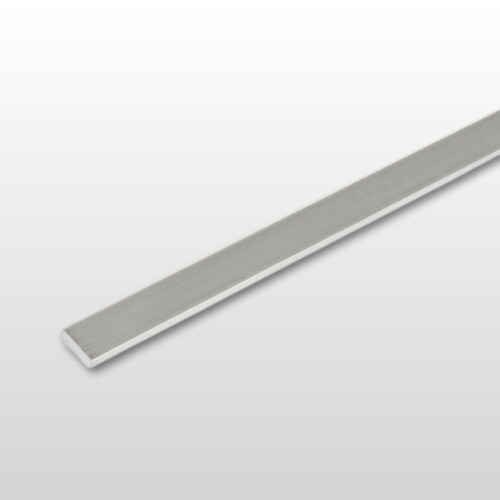

133 assaults

10 x 3 x 1000 (no fast.)

153 assaults

Choose the right Bus bars for your installation

When choosing a Bus bar, it is important to consider how the installation is structured and what requirements there are for grounding and service.

Look in particular at:

- Number of connections – should be sufficient for both current and future needs

- Conductor cross-section – adapt to currents and standard requirements

- Mounting – DIN rail or directly on mounting plate

- Material – copper or brass depending on application

A correctly dimensioned Bus bar provides a clear structure in the control cabinet and reduces the risk of incorrect connections.

Copper or brass Bus bars?

Copper Bus bars

Copper is the most common material for grounding bars in electrical cabinets.

Advantages:

- Very low resistance

- High current resistance

- Suitable for main grounding and potential equalization

Copper bars are often used where several protective earths are collected at a common point.

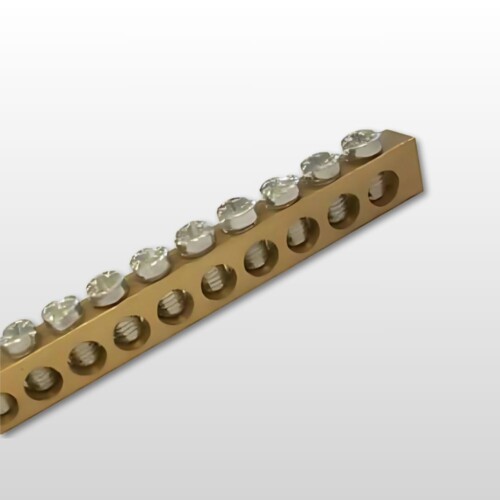

Brass Bus bars

Brass is primarily used where mechanical stability and corrosion resistance are prioritized.

Advantages:

- Robust construction

- Good strength in many connections

- Suitable for environments with variations in temperature and humidity

Brass rails are often used as supplementary grounding points in electrical cabinets.

Potential equalization in control cabinets

The Bus bars is a central part of the electrical cabinet's potential equalization. By collecting all protective earths at a common point, the risk of voltage differences and unwanted currents is reduced.

Correct potential equalization contributes to:

- Increased personal safety

- More stable operation

- Reduced risk of disruption

When might other solutions be more appropriate?

Bus bars are not always the best solution in all installations.

In the following cases, other options may be more suitable:

- For single ground points, direct connection to chassis may be sufficient.

- When connecting shielded cables, shield clamps are often a better choice.

- For high EMC requirements, the grounding bar needs to be supplemented with grounding braids.

➡ Earthing braids – icotek page

Related product areas

FAQ – Frequently asked questions about Bus bars

What is the difference between Bus bars and PE busbar?

A PE busbar is a type of ground busbar intended for protective earth. In practice, the terms are often used synonymously.

How many connections should a Bus bar have?

Always choose a bus bar with more connections than the current need to allow for future expansion.

Do Bus bars need to be marked?

Yes, marking ground points facilitates service and reduces the risk of errors during installation and maintenance.

Do you need help choosing the right Bus bar?

Our experts will be happy to help you find the optimal solution for your installation.